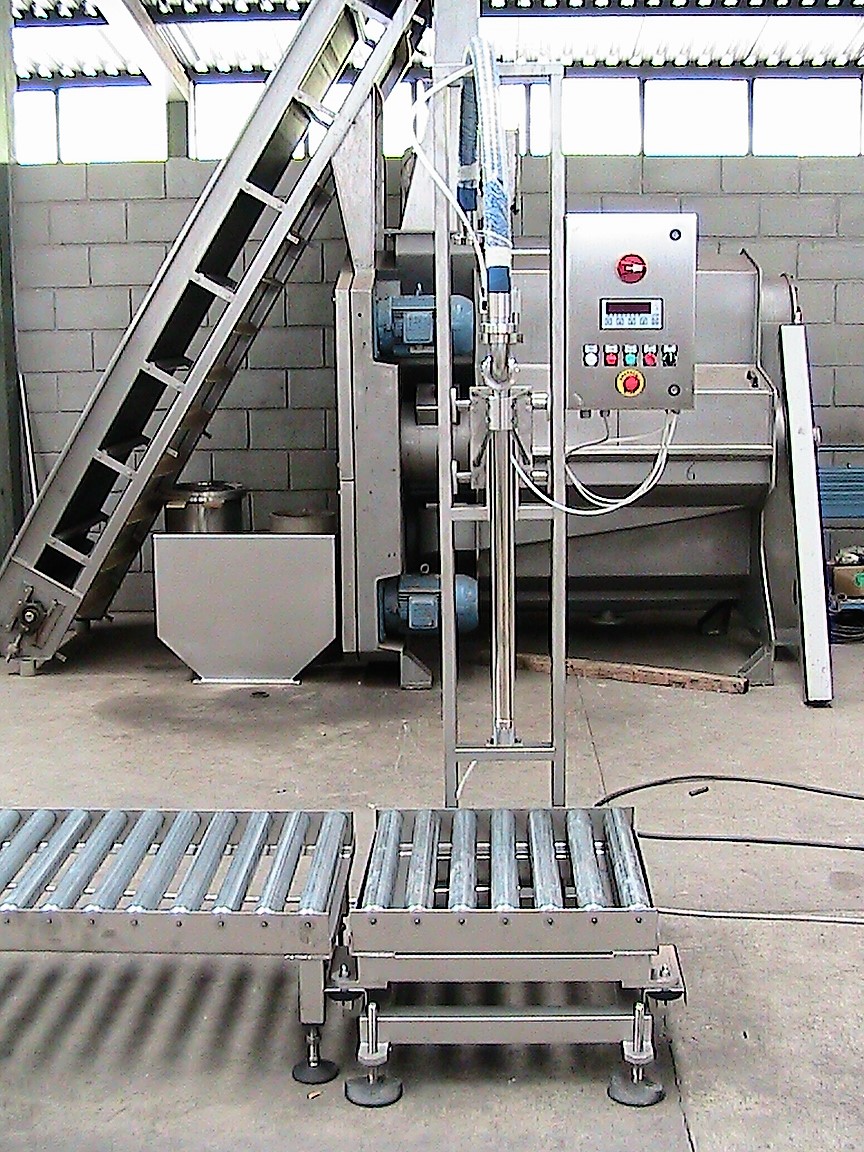

Single or double headed filling machine for cylindrical and plastic barrels, buckets, and bins

One head filling machine for drums, buckets, and bins

This is non-aseptic equipment, equipped with one head in line for filling one packaging at a time, mounted on a support structure and its complete flexible tube for the feeding of the product.

A list of packaging that can be used described below as follow:

The equipment can be used for the filling of hot products (maximum 100ºC hot fill) or products for later freezing with the temperature near 0ºC.

Two versions available:

Launch: EA-2C-SB Filling Machine – Agro

The Aseptic Filler – AGRO Version was developed for Bag in Box filling processes intended for the agricultural sector, serving applications such as biofertilizers, inoculants, live products, liquid fertilizers and similar inputs. This version uses ozone for sterilization, ensuring the microbiological integrity of the process and offering a controlled environment for sensitive products. Compatible with aseptic bags from 3 to 20 liters, the solution ensures filling precision and product stability throughout the entire filling cycle.

Launch: EA-2C-SB Filling Machine – Agro and Dairy Versions

Tropical Food Machinery, from Pouso Alegre (MG), launches new Bag in Box aseptic filling machines in Agro and Dairy versions. The Agro version uses ozone for sterilization, ideal for inoculants and biofertilizers. The Dairy version uses hydrogen peroxide, ensuring safety in the packaging of dairy bases and Low Acid products. Low acidity products meet FDA (USA) standards, ensuring quality and export. TFM also maintains the standard Aseptic version, for pulps and tomatoes. More versatility and the same engineering excellence — Tropical Food Machinery.