Fruit pulp and juice defroster

Fruit Pulp and Juice Defroster

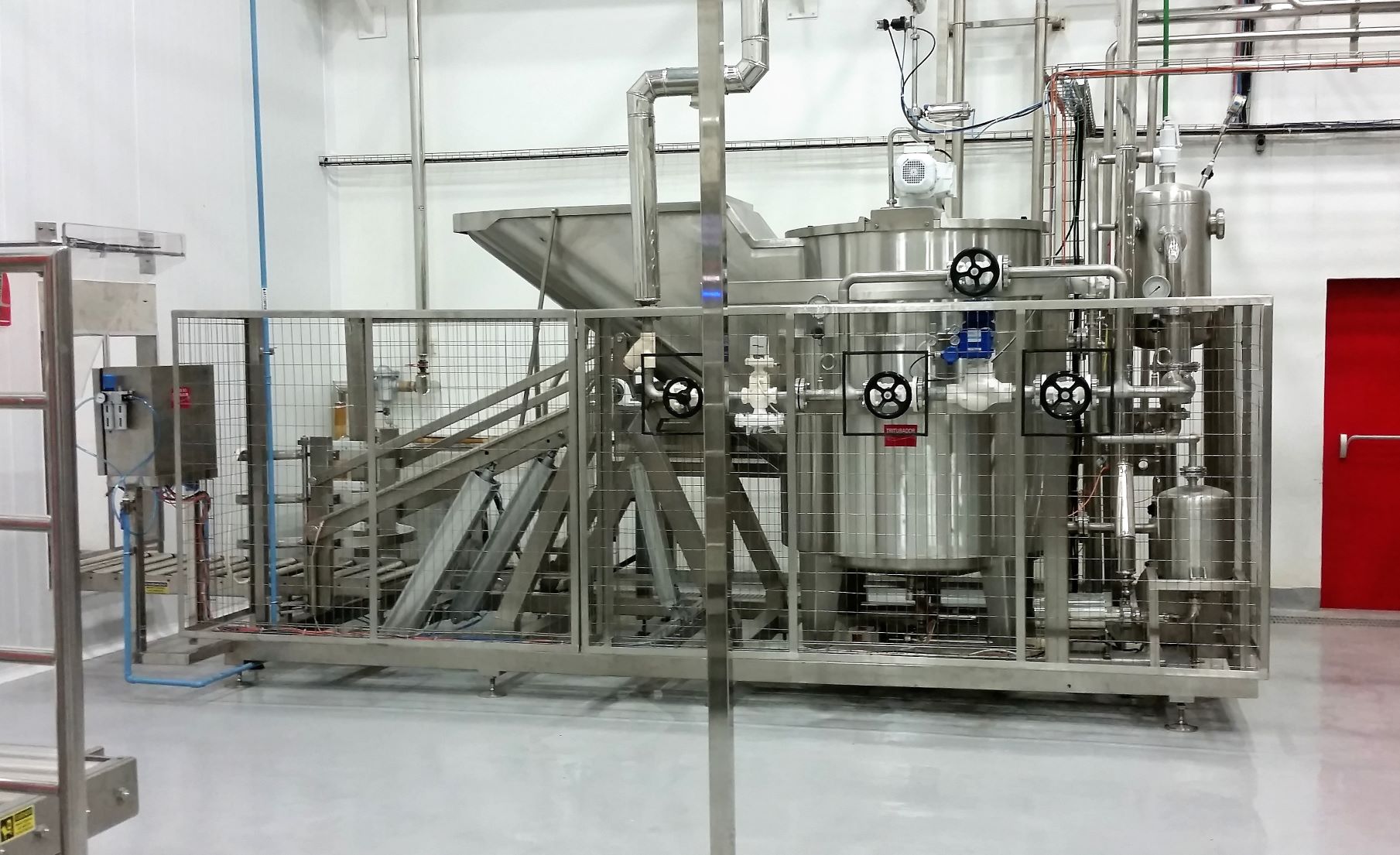

Pulp and juice automated defroster system in 200 liters capacity barrels.

The drums should stay defrosting between 24 to 72 hours exposed to a controlled temperature, according to the temperature of the refrigerating chamber. The purpose is to defrost the external layer allowing the handling of the ice block.

Once ready, the barrel, after the storage bags opened, they are put on a platform of the defroster tank, and then they are lifted and overturned. The ice block, at this time, is scraped by the scraping system and tank agitation.

The pulp is defrosted using steam straight to the cover of the defroster tank, meanwhile the scraping system and agitation remain on; the process is controlled by a pressure transmitter setting the temperature between 0ºC and 10ºC.

Launch: EA-2C-SB Filling Machine – Agro

The Aseptic Filler – AGRO Version was developed for Bag in Box filling processes intended for the agricultural sector, serving applications such as biofertilizers, inoculants, live products, liquid fertilizers and similar inputs. This version uses ozone for sterilization, ensuring the microbiological integrity of the process and offering a controlled environment for sensitive products. Compatible with aseptic bags from 3 to 20 liters, the solution ensures filling precision and product stability throughout the entire filling cycle.

Launch: EA-2C-SB Filling Machine – Agro and Dairy Versions

Tropical Food Machinery, from Pouso Alegre (MG), launches new Bag in Box aseptic filling machines in Agro and Dairy versions. The Agro version uses ozone for sterilization, ideal for inoculants and biofertilizers. The Dairy version uses hydrogen peroxide, ensuring safety in the packaging of dairy bases and Low Acid products. Low acidity products meet FDA (USA) standards, ensuring quality and export. TFM also maintains the standard Aseptic version, for pulps and tomatoes. More versatility and the same engineering excellence — Tropical Food Machinery.