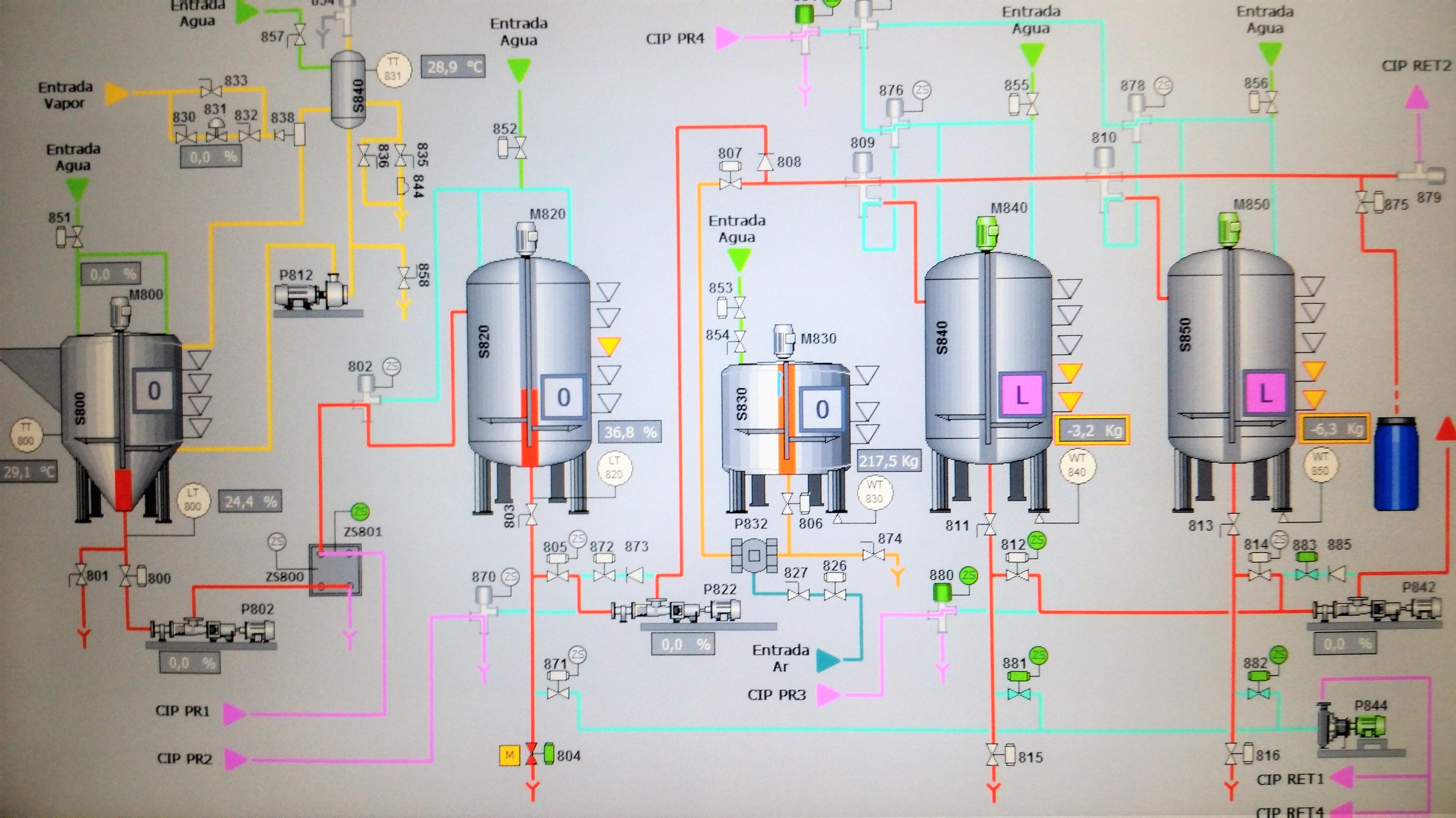

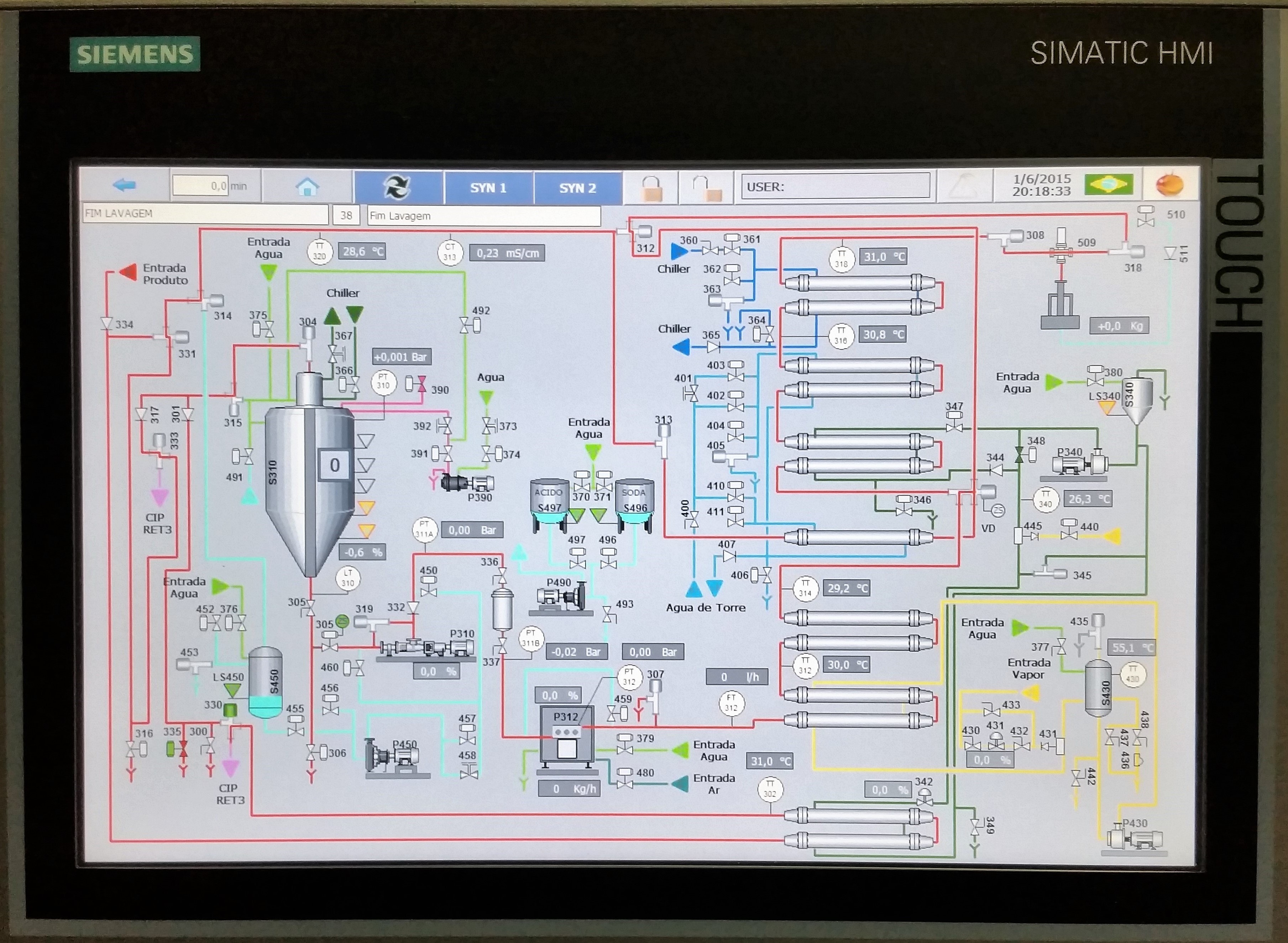

CIP Central automation

CIP Central automation

The automated and centralized CIP system offers cleaning with total security by using recirculation of detergents and sanitizers in appropriate temperatures, besides it can guarantee a superior drag speeds upon surfaces more than needed, and speeds that can guarantee the necessary turbulence for cleaning pipes and connections as well.

When using the tank of recovered water, Central CIP allows reducing up to 40% the consumption of fresh water. At the rinsing time, the consumption of water can be scheduled to the minimum consumption, guaranteeing the necessary time, determined from the analyses of the residual water done by the lab. Likewise the first rinsing dragging out the existing dirt, guaranteeing this way the complete removal of detergents and sanitizers.

Detergents and sanitizers which are discharged during the cycle of the aseptic cleaning system are recovered by the Central CIP, and the consumption of those materials used for cleaning tanks and pipelines is reduced to the maximum as possible.

The follow steps are applied in the cleaning cycle of tubing sections or tanks:

Automation of the system avoids basic mistakes from operators, which can jeopardize the suitability of the production. TFM provides support for modification of the existing units by providing all instrumentation, valves and other components. The cycles are performed automatically.

Launch: EA-2C-SB Filling Machine – Agro

The Aseptic Filler – AGRO Version was developed for Bag in Box filling processes intended for the agricultural sector, serving applications such as biofertilizers, inoculants, live products, liquid fertilizers and similar inputs. This version uses ozone for sterilization, ensuring the microbiological integrity of the process and offering a controlled environment for sensitive products. Compatible with aseptic bags from 3 to 20 liters, the solution ensures filling precision and product stability throughout the entire filling cycle.

Launch: EA-2C-SB Filling Machine – Agro and Dairy Versions

Tropical Food Machinery, from Pouso Alegre (MG), launches new Bag in Box aseptic filling machines in Agro and Dairy versions. The Agro version uses ozone for sterilization, ideal for inoculants and biofertilizers. The Dairy version uses hydrogen peroxide, ensuring safety in the packaging of dairy bases and Low Acid products. Low acidity products meet FDA (USA) standards, ensuring quality and export. TFM also maintains the standard Aseptic version, for pulps and tomatoes. More versatility and the same engineering excellence — Tropical Food Machinery.