Aseptic storage system

Aseptic storage system

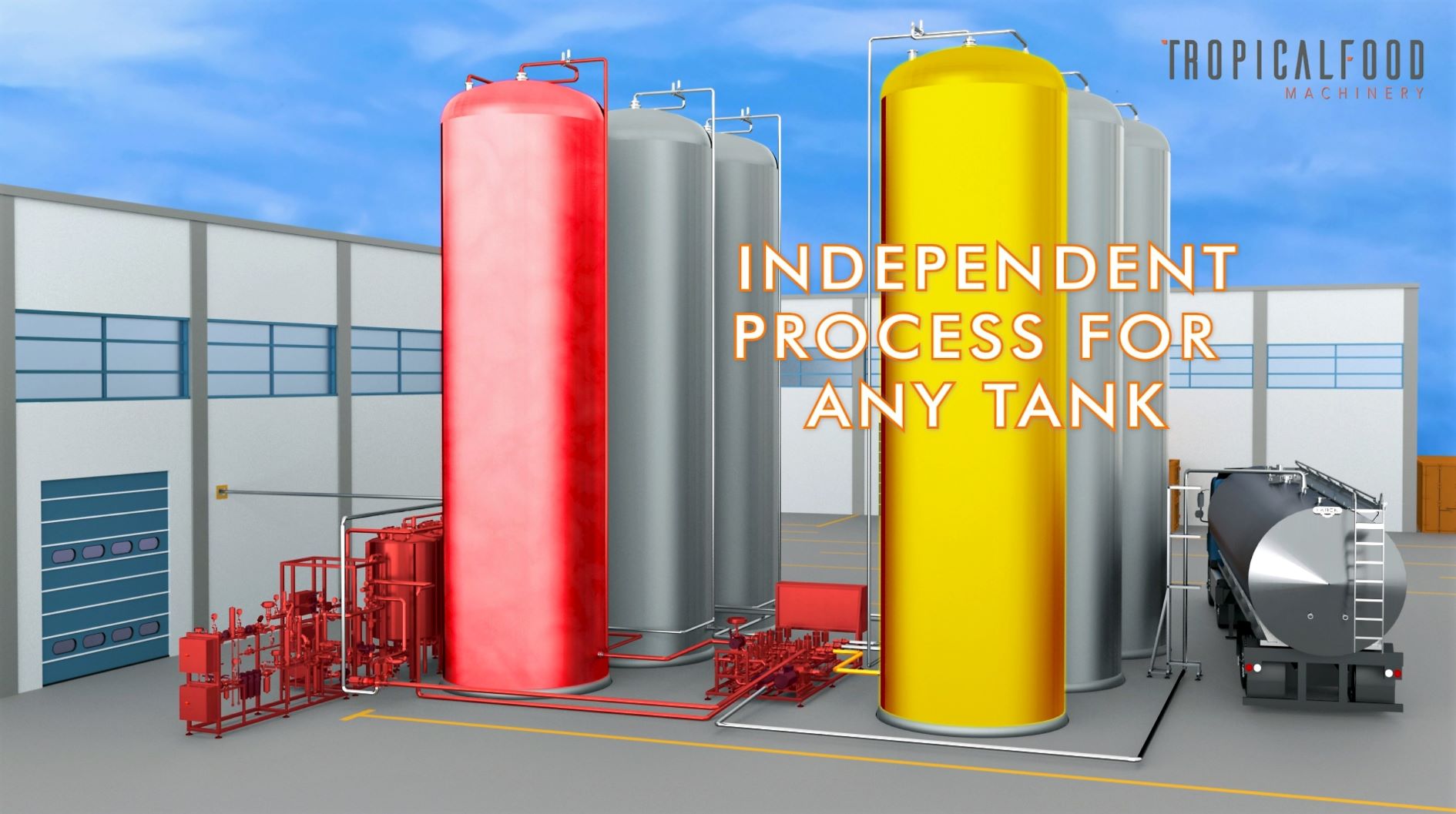

The Tropical Food Machinery Aseptic Storage System has been developed for intermediate and long-term storage of liquids submitted to sterilization treatment. The main advantages offered by the aseptic storage system are:

The concept is simple, juices or purees coming directly from a sterilizer are stored in aseptic tanks at room temperature, without the need for cooling systems, keeping their natural characteristics unchanged.

The homogeneity of the product is guaranteed even in the presence of pulp or fibers, thanks to the installation of a magnetic stirrer.

If the product is consumed in the same unit, it is possible to feed the packaging lines from the storage tank itself. Otherwise, if the product is moved to another location, the product can be aseptically transferred to a tank truck with a capacity of up to 25tons.

All work phases are automatically controlled by a supervisory SCADA system, as well as the cycles of washing, sterilization, sterile pressurizing, filling and emptying. The tanks can be operated independently, thanks to a cluster of integrated aseptic valves.

All critical work parameters, such as temperatures and pressures, are constantly monitored to ensure maximum product safety and traceability of operations.

The total capacity and number of tanks are determined according to the production capacity and the variety of products to be stored.

Launch: EA-2C-SB Filling Machine – Agro

The Aseptic Filler – AGRO Version was developed for Bag in Box filling processes intended for the agricultural sector, serving applications such as biofertilizers, inoculants, live products, liquid fertilizers and similar inputs. This version uses ozone for sterilization, ensuring the microbiological integrity of the process and offering a controlled environment for sensitive products. Compatible with aseptic bags from 3 to 20 liters, the solution ensures filling precision and product stability throughout the entire filling cycle.

Launch: EA-2C-SB Filling Machine – Agro and Dairy Versions

Tropical Food Machinery, from Pouso Alegre (MG), launches new Bag in Box aseptic filling machines in Agro and Dairy versions. The Agro version uses ozone for sterilization, ideal for inoculants and biofertilizers. The Dairy version uses hydrogen peroxide, ensuring safety in the packaging of dairy bases and Low Acid products. Low acidity products meet FDA (USA) standards, ensuring quality and export. TFM also maintains the standard Aseptic version, for pulps and tomatoes. More versatility and the same engineering excellence — Tropical Food Machinery.