Remote Supervisory System "SCADA"

SUPERVISION SYSTEM "SCADA"

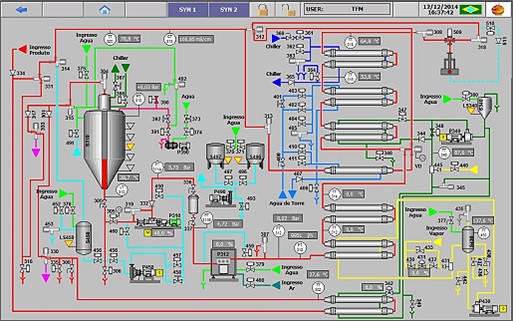

Remote Supervisory System SCADA is a workstation that allows you to control all factory equipment from a remote room. The control room can be in the plant itself or in another location according to customer's requirement. The software allows:

• Start / stop equipment;

• Open / close / adjust valves;

• Define all temperature and pressure control parameters;

• Define in general all other equipment parameters.

The software will store critical production parameters (temperatures, pressures, schedules, alarms) and create trend files with easy display for audit or control purposes, which can also be printed in physical copy.

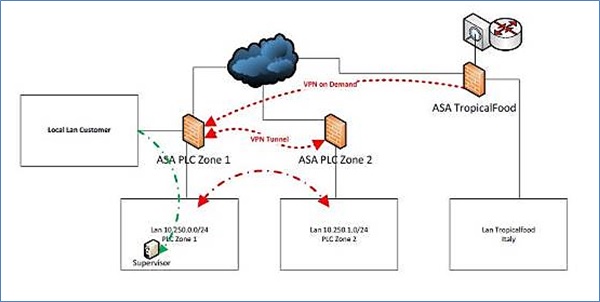

In order to provide a remote service, an industrial network must first be created that puts the various PLCs and operation panels in communication. The type of network we are going to offer is an industrial Ethernet based network from Siemens. It is also possible to expand the network and access all the machines that will be added in the future. Creating a single network will centrally collect data from all the CPs listed above and will make this data available to the SQL server client using a SCADA system. The SCADA system we can offer is Siemens Wincc v.7.0.

Launch: EA-2C-SB Filling Machine – Agro

The Aseptic Filler – AGRO Version was developed for Bag in Box filling processes intended for the agricultural sector, serving applications such as biofertilizers, inoculants, live products, liquid fertilizers and similar inputs. This version uses ozone for sterilization, ensuring the microbiological integrity of the process and offering a controlled environment for sensitive products. Compatible with aseptic bags from 3 to 20 liters, the solution ensures filling precision and product stability throughout the entire filling cycle.

Launch: EA-2C-SB Filling Machine – Agro and Dairy Versions

Tropical Food Machinery, from Pouso Alegre (MG), launches new Bag in Box aseptic filling machines in Agro and Dairy versions. The Agro version uses ozone for sterilization, ideal for inoculants and biofertilizers. The Dairy version uses hydrogen peroxide, ensuring safety in the packaging of dairy bases and Low Acid products. Low acidity products meet FDA (USA) standards, ensuring quality and export. TFM also maintains the standard Aseptic version, for pulps and tomatoes. More versatility and the same engineering excellence — Tropical Food Machinery.