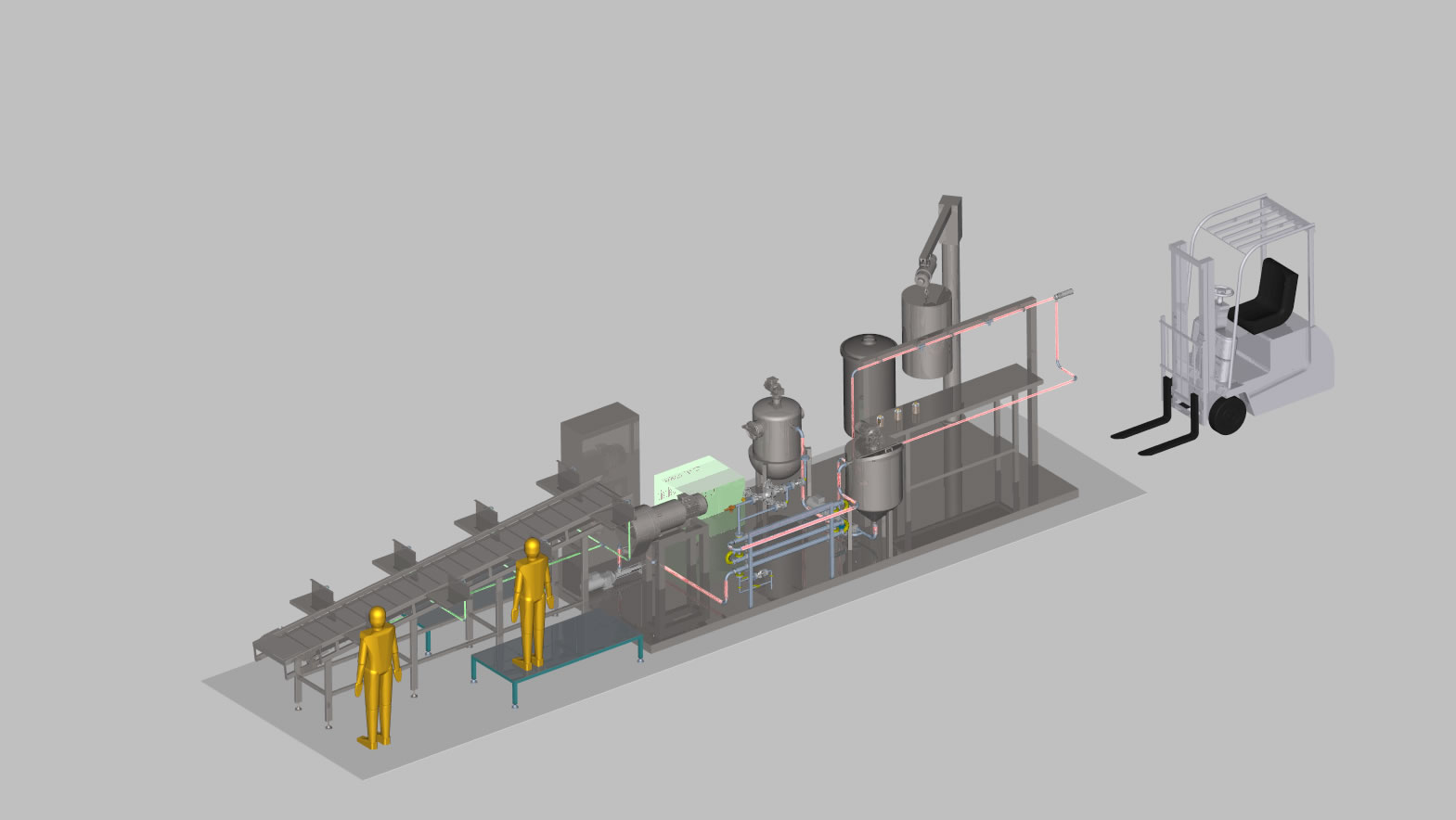

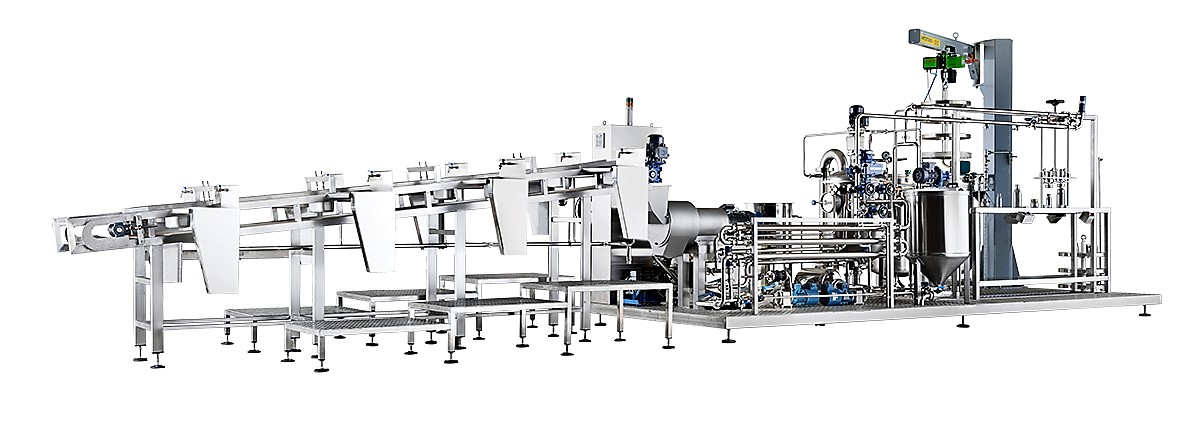

Micro Industry Line TF 200

Micro industry line TF 200

Multifruit micro industry was designed with the purpose to meet small factories or cooperatives, as they want to start processing various fruits with a low initial investment. The great versatility of this line allows producing juices, pulps and jellies made for glass jars or bottles.

The production capacity is up to 2,000kg per day or 250kg per hour of in natura fruits.

Production of: Natural pulps and juices of fruits and jellies.

The micro industry solution offers many advantages as listed below:

The line is divided into three sections:

_baixa.jpg)

Launch: EA-2C-SB Filling Machine – Agro

The Aseptic Filler – AGRO Version was developed for Bag in Box filling processes intended for the agricultural sector, serving applications such as biofertilizers, inoculants, live products, liquid fertilizers and similar inputs. This version uses ozone for sterilization, ensuring the microbiological integrity of the process and offering a controlled environment for sensitive products. Compatible with aseptic bags from 3 to 20 liters, the solution ensures filling precision and product stability throughout the entire filling cycle.

Launch: EA-2C-SB Filling Machine – Agro and Dairy Versions

Tropical Food Machinery, from Pouso Alegre (MG), launches new Bag in Box aseptic filling machines in Agro and Dairy versions. The Agro version uses ozone for sterilization, ideal for inoculants and biofertilizers. The Dairy version uses hydrogen peroxide, ensuring safety in the packaging of dairy bases and Low Acid products. Low acidity products meet FDA (USA) standards, ensuring quality and export. TFM also maintains the standard Aseptic version, for pulps and tomatoes. More versatility and the same engineering excellence — Tropical Food Machinery.