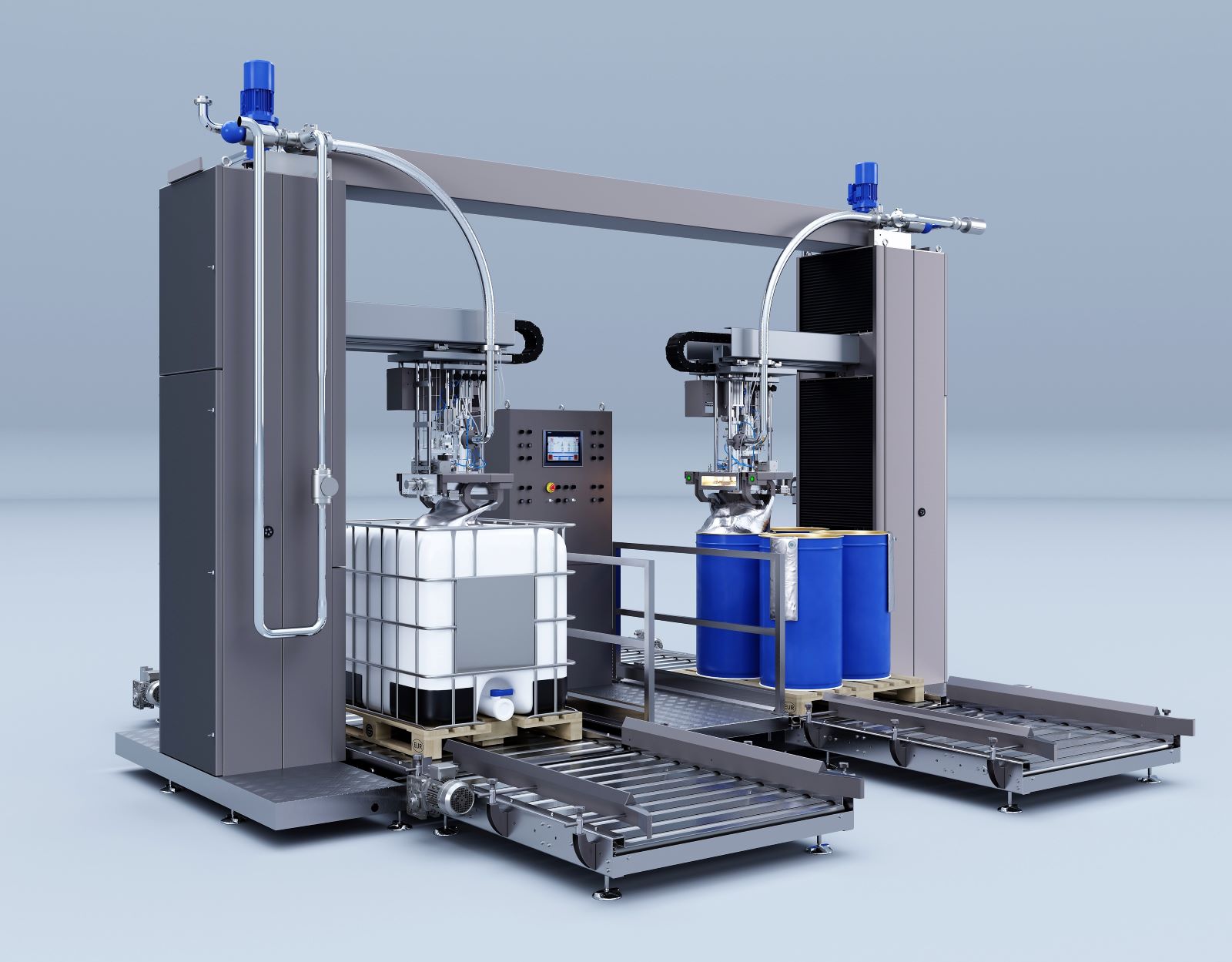

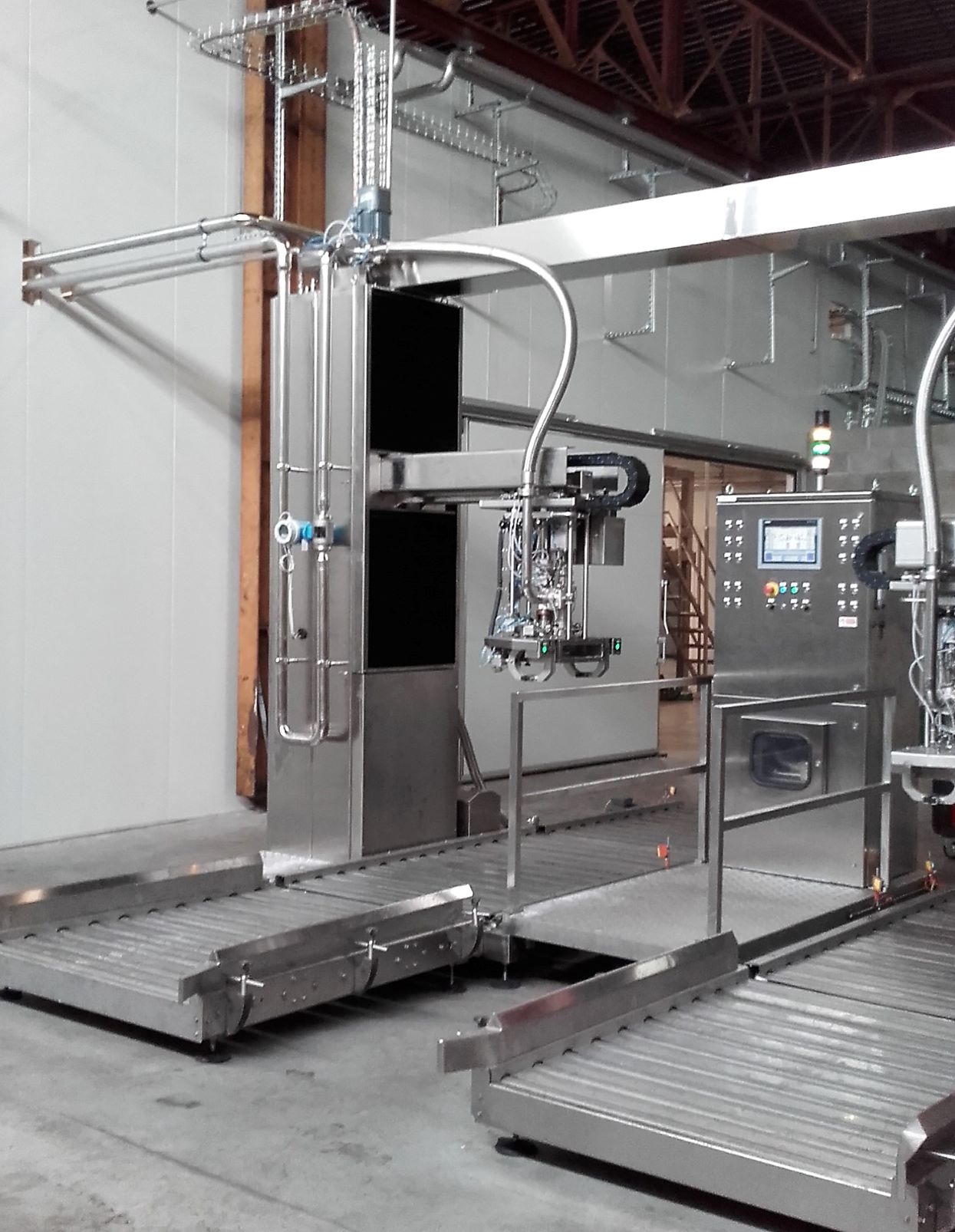

Aseptic Filler TF EA-2C-BD

Aseptic Filler TF EA-2C-BD

Aseptic filler especially projected to the filling of pre-sterilized flexible bags of multiple films with capacities from 200 to 1000 liters. They are ideal to liquid, semi liquid, crushed with small pieces and viscous food products.

The equipment can be furnished with a 1” standard nozzle or a 2” nozzle for products with chunks in small dimensions.

All operations as opening, filling and sealing are fully automatic except when placing the aseptic bag, which must be done manually.

The movements are performed through a pneumatic system, the sterilization is done by a thermal system using steam, and the control of temperature and weight is done by an electronic system. A microprocessor – PLC controls all the process involving: managing functions, programming all the phases of CIP washing, sterilizing, diagnosing while filling to point errors and malfunctions. The panel has a touch screen HMI interface to monitor operations and alarms.

General information:

Launch: EA-2C-SB Filling Machine – Agro

The Aseptic Filler – AGRO Version was developed for Bag in Box filling processes intended for the agricultural sector, serving applications such as biofertilizers, inoculants, live products, liquid fertilizers and similar inputs. This version uses ozone for sterilization, ensuring the microbiological integrity of the process and offering a controlled environment for sensitive products. Compatible with aseptic bags from 3 to 20 liters, the solution ensures filling precision and product stability throughout the entire filling cycle.

Launch: EA-2C-SB Filling Machine – Agro and Dairy Versions

Tropical Food Machinery, from Pouso Alegre (MG), launches new Bag in Box aseptic filling machines in Agro and Dairy versions. The Agro version uses ozone for sterilization, ideal for inoculants and biofertilizers. The Dairy version uses hydrogen peroxide, ensuring safety in the packaging of dairy bases and Low Acid products. Low acidity products meet FDA (USA) standards, ensuring quality and export. TFM also maintains the standard Aseptic version, for pulps and tomatoes. More versatility and the same engineering excellence — Tropical Food Machinery.