Fruit pulp and juice defroster

Fruit Pulp and Juice Defroster

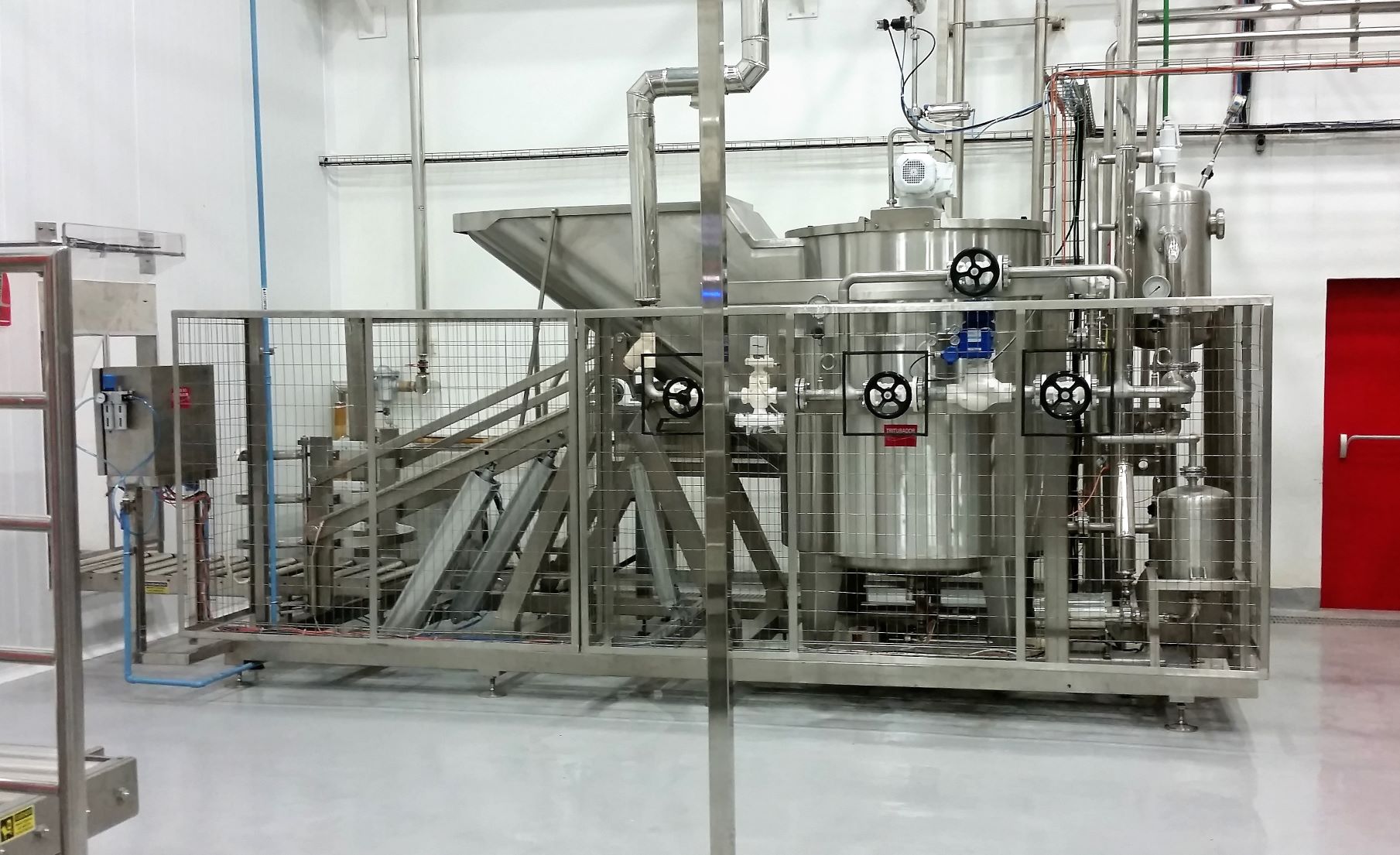

Pulp and juice automated defroster system in 200 liters capacity barrels.

The drums should stay defrosting between 24 to 72 hours exposed to a controlled temperature, according to the temperature of the refrigerating chamber. The purpose is to defrost the external layer allowing the handling of the ice block.

Once ready, the barrel, after the storage bags opened, they are put on a platform of the defroster tank, and then they are lifted and overturned. The ice block, at this time, is scraped by the scraping system and tank agitation.

The pulp is defrosted using steam straight to the cover of the defroster tank, meanwhile the scraping system and agitation remain on; the process is controlled by a pressure transmitter setting the temperature between 0ºC and 10ºC.

Apis Flora - Concentrated Propolis Line

In 2019, we completed the delivery of a concentrated propolis production line through alcoholic extraction and subsequent vacuum evaporation. The process involves the propolis, initially in the form of wax from the apiary, being added to grain alcohol within a process tank specifically designed for this purpose. In the mixing tank, the product is kept constantly stirred, undergoing successive heating and cooling operations over many hours. After this period, the propolis will be diluted. The settled sediment is discarded, and the product is sent to the concentrator for alcohol evaporation and propolis concentration. The concentration pot facilitates vacuum evaporation, and the evaporated alcohol is recovered in an indirect condenser and sent back to the alcohol accumulation tank. The final product is pure and concentrated propolis. All equipment was constructed following safety standards for explosive atmospheres and ATEX certification. Currently, the line is in perfect operation, adding value to our customer.