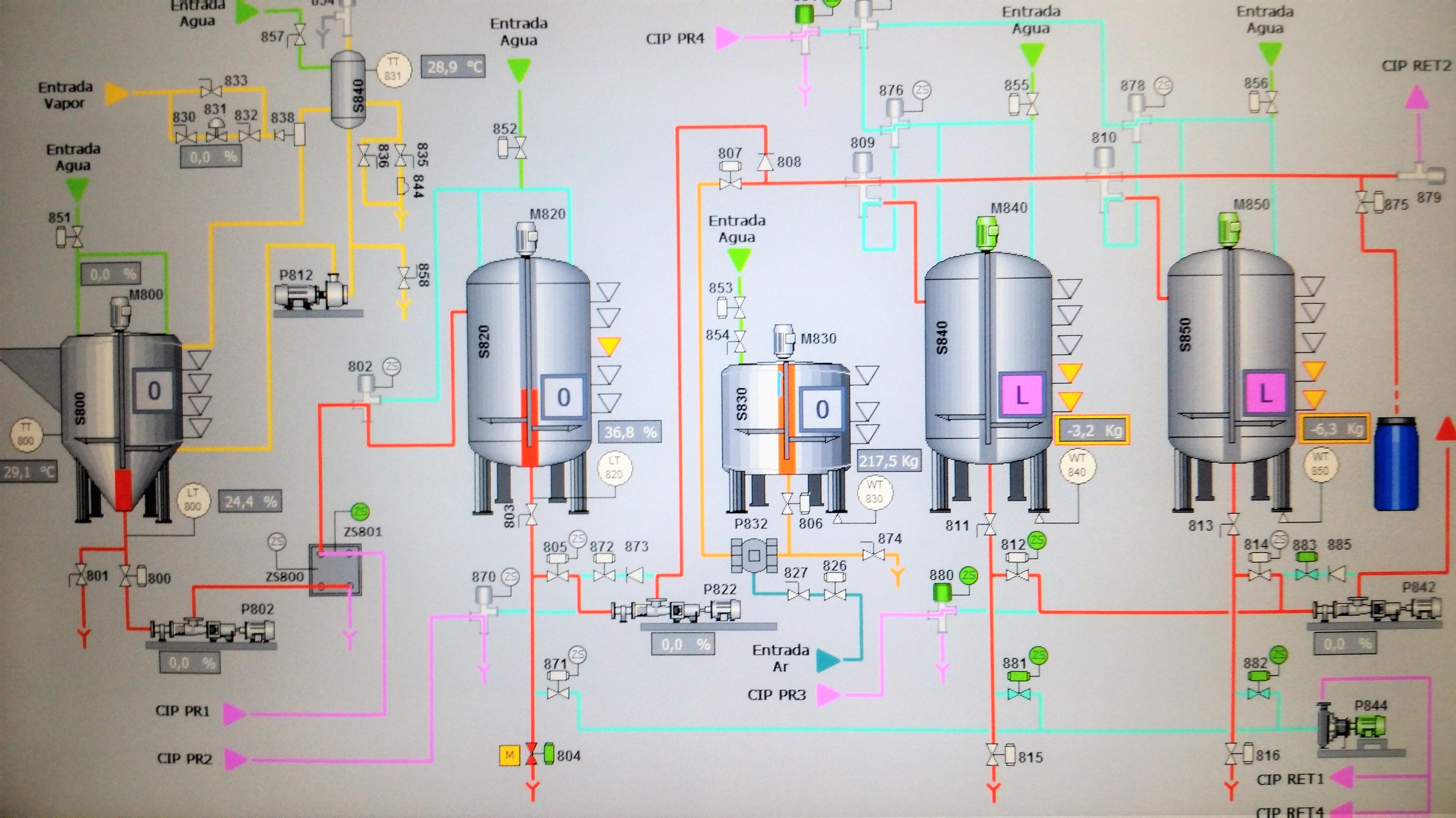

CIP Central automation

CIP Central automation

The automated and centralized CIP system offers cleaning with total security by using recirculation of detergents and sanitizers in appropriate temperatures, besides it can guarantee a superior drag speeds upon surfaces more than needed, and speeds that can guarantee the necessary turbulence for cleaning pipes and connections as well.

When using the tank of recovered water, Central CIP allows reducing up to 40% the consumption of fresh water. At the rinsing time, the consumption of water can be scheduled to the minimum consumption, guaranteeing the necessary time, determined from the analyses of the residual water done by the lab. Likewise the first rinsing dragging out the existing dirt, guaranteeing this way the complete removal of detergents and sanitizers.

Detergents and sanitizers which are discharged during the cycle of the aseptic cleaning system are recovered by the Central CIP, and the consumption of those materials used for cleaning tanks and pipelines is reduced to the maximum as possible.

The follow steps are applied in the cleaning cycle of tubing sections or tanks:

Automation of the system avoids basic mistakes from operators, which can jeopardize the suitability of the production. TFM provides support for modification of the existing units by providing all instrumentation, valves and other components. The cycles are performed automatically.

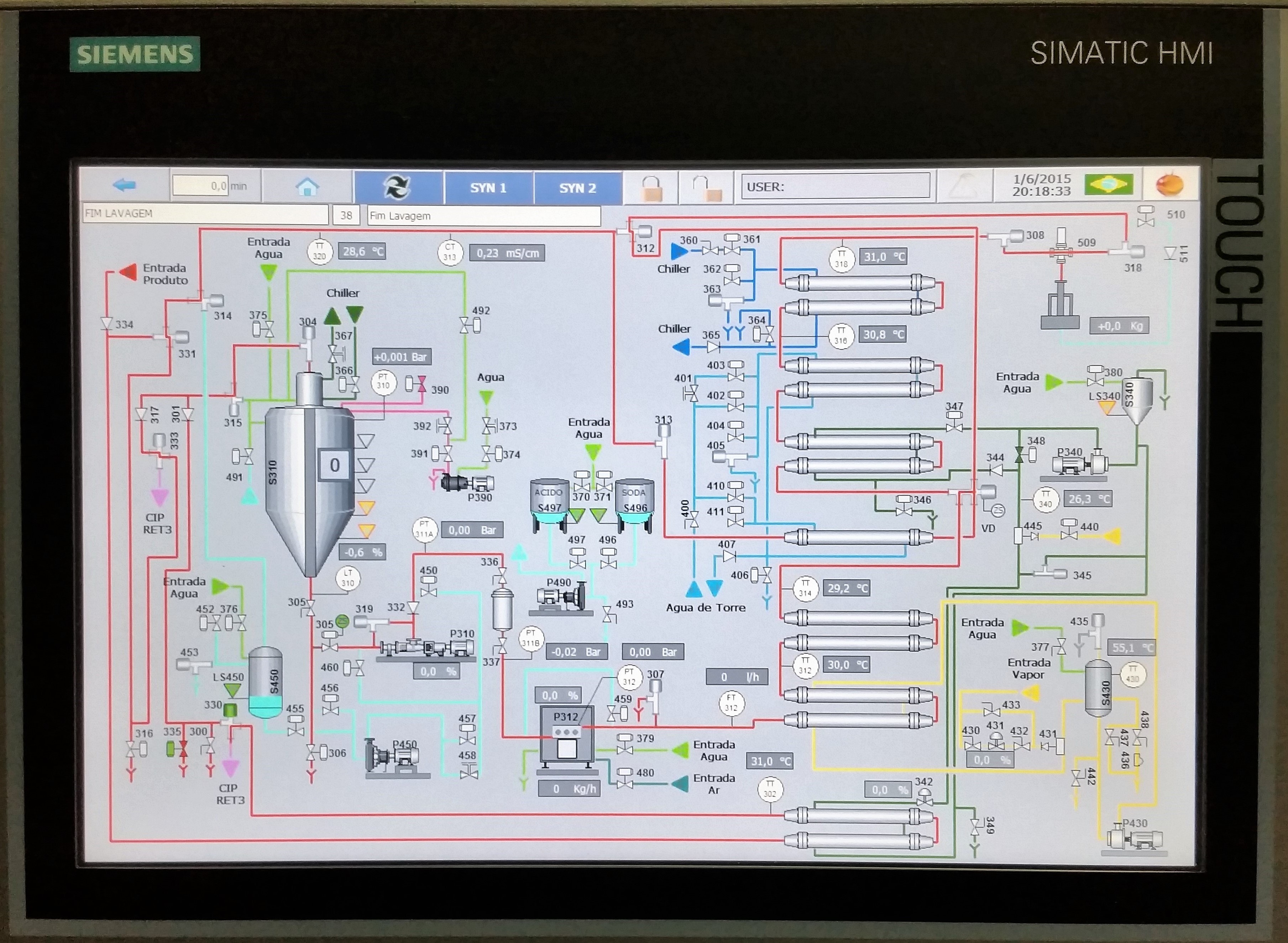

Apis Flora - Concentrated Propolis Line

In 2019, we completed the delivery of a concentrated propolis production line through alcoholic extraction and subsequent vacuum evaporation. The process involves the propolis, initially in the form of wax from the apiary, being added to grain alcohol within a process tank specifically designed for this purpose. In the mixing tank, the product is kept constantly stirred, undergoing successive heating and cooling operations over many hours. After this period, the propolis will be diluted. The settled sediment is discarded, and the product is sent to the concentrator for alcohol evaporation and propolis concentration. The concentration pot facilitates vacuum evaporation, and the evaporated alcohol is recovered in an indirect condenser and sent back to the alcohol accumulation tank. The final product is pure and concentrated propolis. All equipment was constructed following safety standards for explosive atmospheres and ATEX certification. Currently, the line is in perfect operation, adding value to our customer.