Remote Supervisory System "SCADA"

SUPERVISION SYSTEM "SCADA"

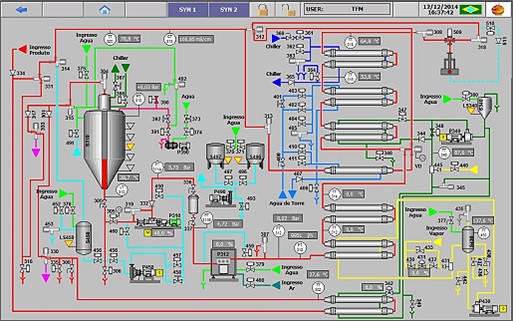

Remote Supervisory System SCADA is a workstation that allows you to control all factory equipment from a remote room. The control room can be in the plant itself or in another location according to customer's requirement. The software allows:

• Start / stop equipment;

• Open / close / adjust valves;

• Define all temperature and pressure control parameters;

• Define in general all other equipment parameters.

The software will store critical production parameters (temperatures, pressures, schedules, alarms) and create trend files with easy display for audit or control purposes, which can also be printed in physical copy.

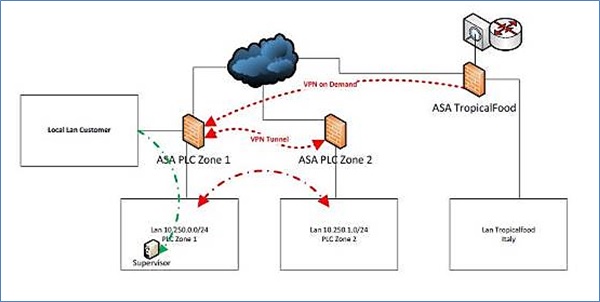

In order to provide a remote service, an industrial network must first be created that puts the various PLCs and operation panels in communication. The type of network we are going to offer is an industrial Ethernet based network from Siemens. It is also possible to expand the network and access all the machines that will be added in the future. Creating a single network will centrally collect data from all the CPs listed above and will make this data available to the SQL server client using a SCADA system. The SCADA system we can offer is Siemens Wincc v.7.0.

Apis Flora - Concentrated Propolis Line

In 2019, we completed the delivery of a concentrated propolis production line through alcoholic extraction and subsequent vacuum evaporation. The process involves the propolis, initially in the form of wax from the apiary, being added to grain alcohol within a process tank specifically designed for this purpose. In the mixing tank, the product is kept constantly stirred, undergoing successive heating and cooling operations over many hours. After this period, the propolis will be diluted. The settled sediment is discarded, and the product is sent to the concentrator for alcohol evaporation and propolis concentration. The concentration pot facilitates vacuum evaporation, and the evaporated alcohol is recovered in an indirect condenser and sent back to the alcohol accumulation tank. The final product is pure and concentrated propolis. All equipment was constructed following safety standards for explosive atmospheres and ATEX certification. Currently, the line is in perfect operation, adding value to our customer.