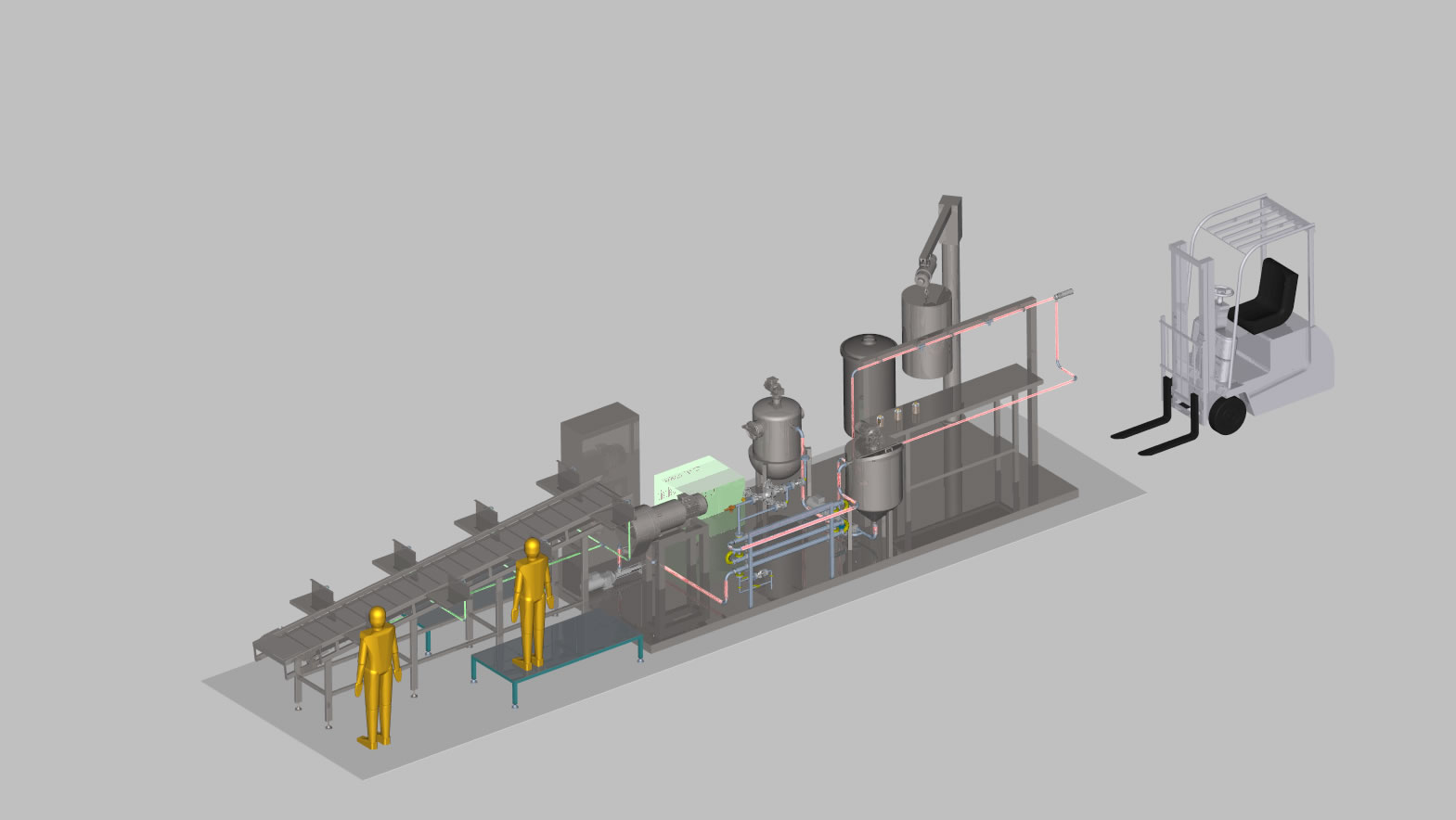

Micro Industry Line TF 200

Micro industry line TF 200

Multifruit micro industry was designed with the purpose to meet small factories or cooperatives, as they want to start processing various fruits with a low initial investment. The great versatility of this line allows producing juices, pulps and jellies made for glass jars or bottles.

The production capacity is up to 2,000kg per day or 250kg per hour of in natura fruits.

Production of: Natural pulps and juices of fruits and jellies.

The micro industry solution offers many advantages as listed below:

The line is divided into three sections:

_baixa.jpg)

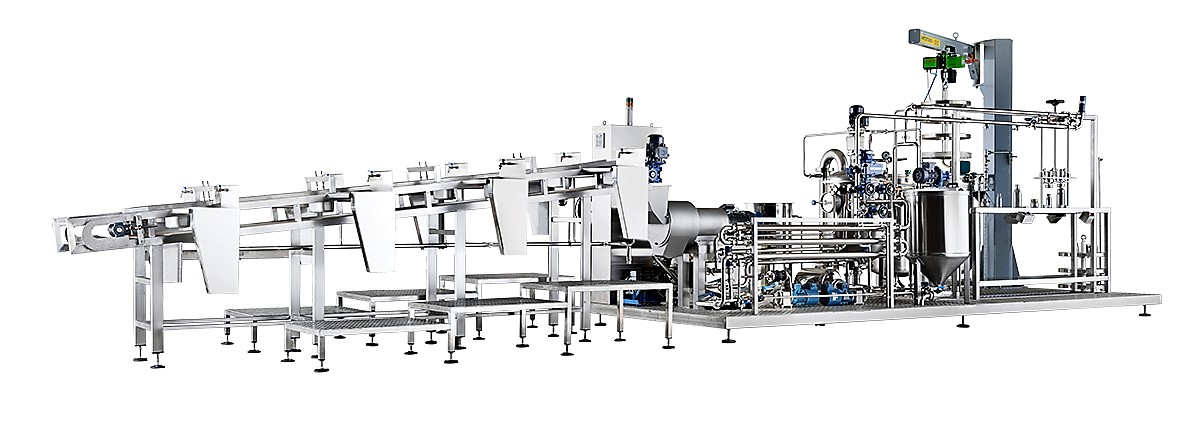

Apis Flora - Concentrated Propolis Line

In 2019, we completed the delivery of a concentrated propolis production line through alcoholic extraction and subsequent vacuum evaporation. The process involves the propolis, initially in the form of wax from the apiary, being added to grain alcohol within a process tank specifically designed for this purpose. In the mixing tank, the product is kept constantly stirred, undergoing successive heating and cooling operations over many hours. After this period, the propolis will be diluted. The settled sediment is discarded, and the product is sent to the concentrator for alcohol evaporation and propolis concentration. The concentration pot facilitates vacuum evaporation, and the evaporated alcohol is recovered in an indirect condenser and sent back to the alcohol accumulation tank. The final product is pure and concentrated propolis. All equipment was constructed following safety standards for explosive atmospheres and ATEX certification. Currently, the line is in perfect operation, adding value to our customer.